Does the brand of fertilizer you use really matter? Short answer is yes, it does. There is a lot more than just N-P-K that makes up a bag of fertilizer. There are a few important things you should look for when selecting a brand of fertilizer.

EEF (Enhanced Efficiency Fertilizer)

The Association of American Plant Food Control Officials (AAPFCO) defines EEFs as products with characteristics that allow increased plant uptake and therefore reduce potential nutrient losses to the environment (e.g., gaseous losses, leaching, or runoff) when compared to an appropriate reference fertilizer that does not contain additives. Controlled or slow-release fertilizer provide solutions that contribute to environmental responsibility:

- Reducing N volatilization and slowing the conversion to nitrate means more N remains available to plants

- With gradual metering of N, uptake by the plant is optimized; less is underutilized, reducing potential loss to the environment

- The result is more efficient nutrient use, meaning your customers can apply less N, which not only benefits the environment; it helps to preserve this vital resource as well

TurfGro fertilizers have several slow release fertilizer options that include technology such as Duration and XCU.

Micronutrients

Micronutrients are essential for soil health and plant growth. Soil analysis shows micronutrient deficiency is common in soil and can be a contributing factor to pest problems and slow germination. If a fertilizer contains one of the common micronutrients (boron, copper, iron, manganese, zinc, magnesium, calcium & sulfur) they will be listed on the label after NPK.

What makes TurfGro fertilizer different from other brands is that it is manufactured and blended locally in market. This allows us to design the formulation to meet the soil needs of that market, adding micronutrients commonly missing.

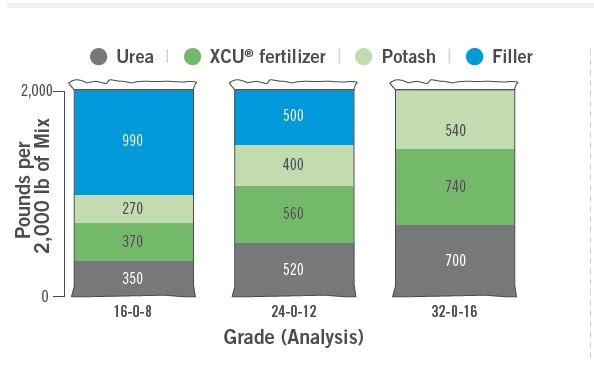

What’s in the Bag?

Typical fertilizer is made up of four components: urea, nitrogen, potash and filler. The first three components provide nutrients to the turf, while “filler” normally doesn’t offer any value. The amount and content of that filler can influence the quality of that turf.

Amount – the more urea, nitrogen and potash in the blend, they less need for filler. So when you select a fertilizer with a higher NPK, you will have less filler in the bag. In addition to NPK, micronutrients like calcium and magnesium reduce the amount of filler blended in the fertilizer.

Content – most higher end fertilizer will use biosolids or other organic-based product as filler. Most less expensive products use limestone, which provides zero nutrition to the soil. It’s less expensive, but you are still paying for product that can’t be used by the turf.

When needed, Horizon’s TurfGro fertilizer commonly use biosolids as the basis for filler, ensuring a higher value product for you.

Pellet Size

In blended fertilizers, the individual particles remain separate in the mixture, and there is a potential for segregation of the nutrients. This problem can be reduced by using materials that are the same size. Properly made blends are generally equal in effectiveness to other compound fertilizers.

You can always find a cheaper bag of fertilizer. But when you look overall cost of the application you will find that a cheaper bag will normally cost you more in the long run. Following a program and using a premium fertilizer like TurfGro will help you deliver healthy, green turf to your client season after season.

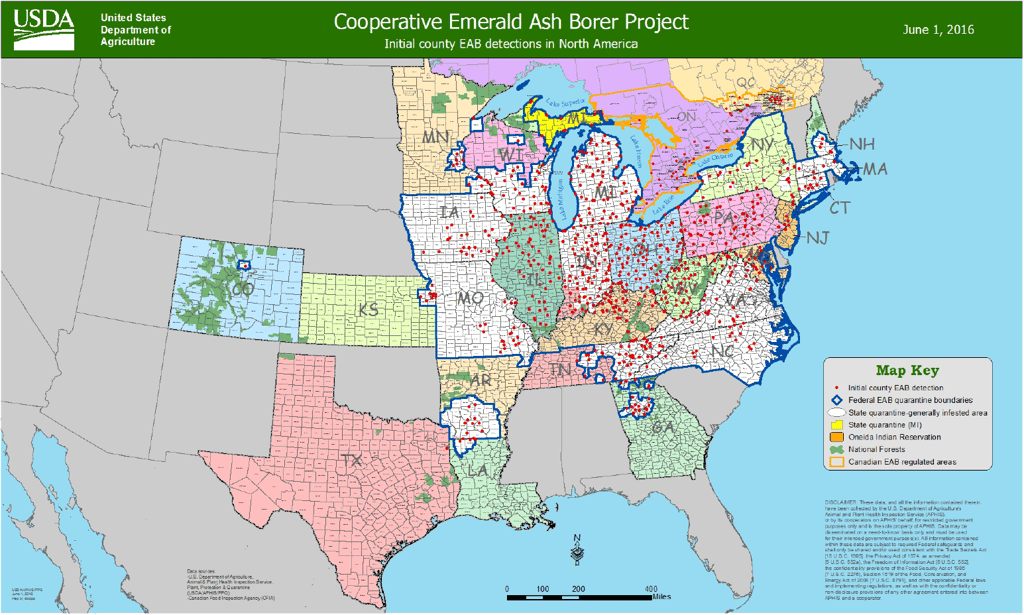

Because emerald ash borers are not native to the U.S., our ash trees don't have any natural defense mechanism against this invasive insect; and once an ash is infected, it generally dies within 2 to 3 years if it's not treated early and effectively. What makes the situation even worse is that infestations often aren't identified until it's too late. And because they can easily be transported in firewood and wood products, it's tough to predict how quickly they will spread across Texas.

Because emerald ash borers are not native to the U.S., our ash trees don't have any natural defense mechanism against this invasive insect; and once an ash is infected, it generally dies within 2 to 3 years if it's not treated early and effectively. What makes the situation even worse is that infestations often aren't identified until it's too late. And because they can easily be transported in firewood and wood products, it's tough to predict how quickly they will spread across Texas. Ash trees with low population densities of EAB often exhibit little evidence of infestation. It's also difficult to identify EAB damage in the winter because they are still in the larvae stage of their lifecycle, feeding on the phloem of the tree.

Ash trees with low population densities of EAB often exhibit little evidence of infestation. It's also difficult to identify EAB damage in the winter because they are still in the larvae stage of their lifecycle, feeding on the phloem of the tree. One of the benefits of Texas being the 26th state invaded by EAB is that there's a solid 10 years of research on the best methods for controlling this pest. Effective treatments have been identified!

One of the benefits of Texas being the 26th state invaded by EAB is that there's a solid 10 years of research on the best methods for controlling this pest. Effective treatments have been identified!

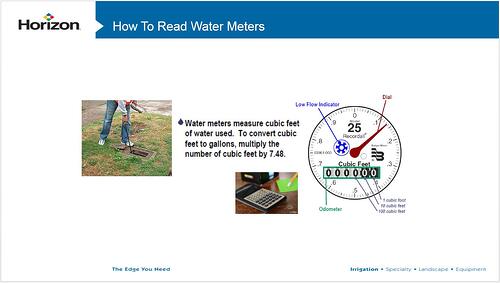

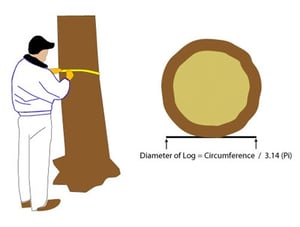

The application rate is 10 gallons of solution per 12” of diameter at breast height (4.5' above the ground). If you don't have a diameter measuring tool, measure the circumference and divide by 3.14. So if you're working with a redwood or pine tree with a 24" diameter, you'll need 20 gallons of solution.

The application rate is 10 gallons of solution per 12” of diameter at breast height (4.5' above the ground). If you don't have a diameter measuring tool, measure the circumference and divide by 3.14. So if you're working with a redwood or pine tree with a 24" diameter, you'll need 20 gallons of solution. To test your spreader's current application rate, measure out an area of 1000 sq ft.

To test your spreader's current application rate, measure out an area of 1000 sq ft.

About Coast Landscaping Inc.

About Coast Landscaping Inc.