The right power equipment can make or break both the day-to-day operation and the long-term success of your business. But it's not enough to just choose the right pieces of equipment, you must also successfully manage the expenses surrounding the acquisition and maintenance of that equipment.

Unless you have a significant amount of cash on hand, it's generally best to finance at least part of your purchase. In fact, over 80% of the commercial power equipment that we sell at Horizon is financed.

But what financial product is best for you? In this article, we'll identify some of the advantages and disadvantages of financing, leasing, and renting commercial power equipment and look at some key questions that will help you determine which option is best for you.

Financing Power Equipment

Financing can be a great tool when there's a piece of equipment that you want to add to your fleet for the long-term, but prefer to keep cash on hand for other expenses. There are two main types of financing available:

1. Installment Loans - Commonly used for larger purchases, installment loans offer predictability. You get a fixed payment at a certain interest rate that pays for the unit over an agreed upon number of payments.

2. Credit Cards & Lines of Credit - Also referred to as revolving credit, credit cards and lines of credit offer more flexibility than a loan. Both can be used for multiple transactions and are automatically renewed as debts are paid off.

Why Finance?

• Financing helps you preserve cash flow by spreading your payments out over time.

• Financing usually offers the most tax deductions (e.g. depreciation, insurance, repairs, taxes, and interest). Be sure to check with your tax professional prior to purchase to confirm what deductions you're eligible for.

Disadvantages of Financing:

• Overall cost is higher than what you would pay if you had purchased the unit outright.

• Payments are typically higher than a lease.

• Repairs not covered under warranty are your responsibility.

Key Questions to Answer Before You Finance:

• Is this a loan, credit line, or credit card?

• What can be purchased with this account (e.g. specific product/manufacturer, accessories, used equipment, repairs & service)?

• What is the down payment?

• What is the monthly payment?

• What is the interest rate?

• What is the total cost over the lifetime of the loan?

• Are there any pre-payment penalties?

• What happens if you miss a payment?

• What are the tax benefits?

Leasing Power Equipment

Leasing can be a great tool for acquiring equipment that you would like to use for the mid to long-term, but it's important to be aware of the terms of the lease because there are different types. Some leases act as an extended rental agreement, but others are structured more like a loan and give you the option to purchase the unit when the lease is over.

Why Lease?

• Leases help you stay current with the latest technology and allow you to keep newer equipment in your fleet.

• Like a loan, a lease allows you to preserve cash flow by spreading payments out over time.

• Lease payments are often lower than loan payments.

• You can usually deduct your monthly payments as an operating expense for tax purposes. Be sure to check with your tax professional beforehand.

• Some leases cover maintenance.

Disadvantages of Leasing:

• Many leases limit the number of hours you can put on the unit and the penalty for going over that limit can be severe.

• Overall cost is often higher than what you would pay if you had purchased the unit outright.

• Leases generally offer fewer tax benefits than loans.

Key Questions to Answer Before You Lease:

• What happens at the end of the lease?

• If you decide to purchase the unit, what will the purchase price be?

• What is the down payment?

• What is the monthly payment?

• What is the interest rate?

• Is there a service contract? What does it cover?

• How many unit hours are you permitted? What is the penalty if you go over those hours?

• What happens if you miss a payment?

• What are the tax benefits?

Renting Power Equipment

Renting can be an excellent short-term solution, especially when it's unlikely that the equipment will become a permanent part of your fleet. But renting is not without risk and the higher cost of renting must be considered to ensure profitability.

Why Rent?

• You need additional equipment for seasonal work or to complete a project that's outside of your normal service offering.

• You want to try out a new piece of equipment before purchasing, financing, or leasing it.

• An important piece of equipment is in the shop and you need an immediate replacement.

Disadvantages of Renting:

• Renting generally costs significantly more than financing or leasing.

• It can be time-consuming to learn how to operate new equipment and to pick it up and return it to the rental company.

• You may be liable for damage to the unit, which can further inflate your costs.

Key Questions to Answer Before You Rent:

• What is the daily/weekly/monthly cost of renting?

• Is there enough margin in the job to cover the cost of a rental?

• Who is responsible for servicing or repairing the unit?

• Under what circumstances are you liable for damage to the unit?

• Do you need insurance coverage? If so, what is the cost?

About Coast Landscaping Inc.

About Coast Landscaping Inc.

To keep your engine safe, it's important to use:

To keep your engine safe, it's important to use: It's a good idea to use an oil that is designed specifically for hydraulic systems. Since it's not an engine oil, Exmark has added zinc back in to their Premium Hydro Oil. This oil stays contained, doesn't burn off, and goes to a higher temperature without breaking down.

It's a good idea to use an oil that is designed specifically for hydraulic systems. Since it's not an engine oil, Exmark has added zinc back in to their Premium Hydro Oil. This oil stays contained, doesn't burn off, and goes to a higher temperature without breaking down.

Following the lowest snowpack ever recorded and with no end to the drought in sight, Governor Edmund G. Brown Jr. today announced actions that will save water, increase enforcement to prevent wasteful water use, streamline the state's drought response, and invest in new technologies that will make California more drought resilient.

Following the lowest snowpack ever recorded and with no end to the drought in sight, Governor Edmund G. Brown Jr. today announced actions that will save water, increase enforcement to prevent wasteful water use, streamline the state's drought response, and invest in new technologies that will make California more drought resilient.

A smart water controller is an essential part of an water efficient irrigation system, but its impact is limited when the rest of the system isn't operating efficiently. When you're installing a new system, it's easier to incorporate complementary water saving techologies and create an efficient system. But when you're working with an existing system, the idea is to make simple adjustments that can have an immediate impact on your customer's water bill.

A smart water controller is an essential part of an water efficient irrigation system, but its impact is limited when the rest of the system isn't operating efficiently. When you're installing a new system, it's easier to incorporate complementary water saving techologies and create an efficient system. But when you're working with an existing system, the idea is to make simple adjustments that can have an immediate impact on your customer's water bill. You can have the right controller and the right spray body, but if the system pressure is too high for your spray nozzle, you'll end up wasting a lot of water. Usually you'll see this in the form of fogging or misting, which atomizes the water and blows it onto sidewalks and hardscapes, greatly reducing the distribution uniformity of the nozzle. When the distribution uniformity of your sprays drops, you have to run the system longer to avoid dry spots.

You can have the right controller and the right spray body, but if the system pressure is too high for your spray nozzle, you'll end up wasting a lot of water. Usually you'll see this in the form of fogging or misting, which atomizes the water and blows it onto sidewalks and hardscapes, greatly reducing the distribution uniformity of the nozzle. When the distribution uniformity of your sprays drops, you have to run the system longer to avoid dry spots. If you're working on a property that has sloped surfaces and you see water seeping out some of the heads, you likely have low head drainage. With low head drainage, every bit of water from the valve to the low head will be wasted every time the water is shut off, which is even more problematic if you're cycle and soaking.

If you're working on a property that has sloped surfaces and you see water seeping out some of the heads, you likely have low head drainage. With low head drainage, every bit of water from the valve to the low head will be wasted every time the water is shut off, which is even more problematic if you're cycle and soaking. With drought becoming a common topic in the news, water restrictions becoming more commonplace, and cash for grass programs paying property owners to pull up their lawns, it's important to be prepared when customers ask you to remove their turf.

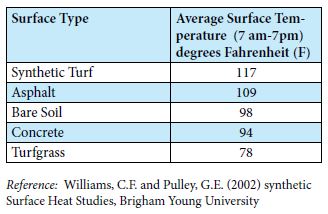

With drought becoming a common topic in the news, water restrictions becoming more commonplace, and cash for grass programs paying property owners to pull up their lawns, it's important to be prepared when customers ask you to remove their turf.